What is the negative pressure weighing chamber cleaning protocol?

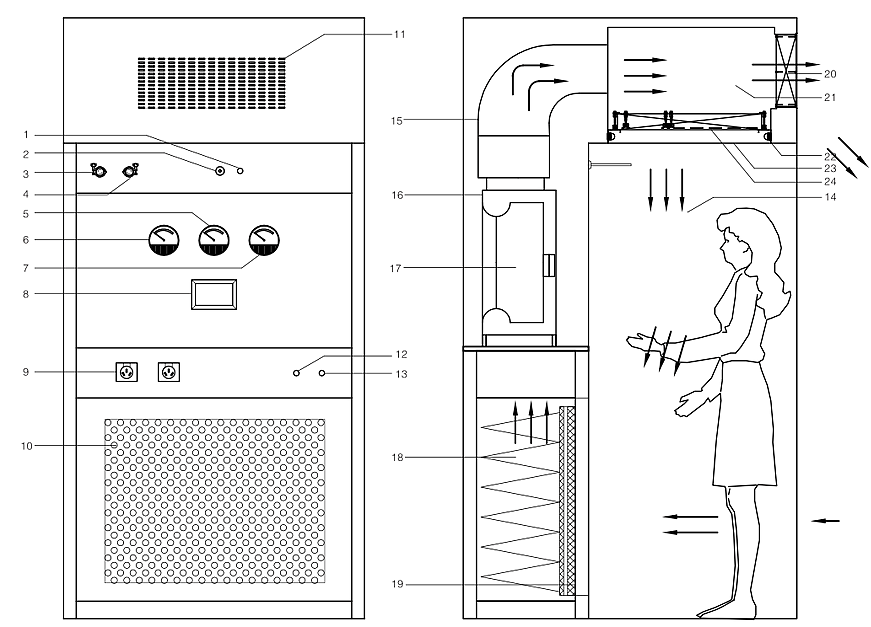

What is the negative pressure weighing chamber cleaning protocol?Negative Pressure Weighing Chamber is a localised purification equipment, mainly used in pharmaceutical, microbiological research, and scientific experiments. It provides a clean environment to prevent cross-contamination and dust spillage. The main feature of a negative pressure weighing chamber is that it can provide vertical unidirectional airflow to generate negative pressure in the working area to prevent dust and reagent spillage. Weighing and dispensing parts and reagents in the chamber can control the spillage of dust and reagents, preventing them from being inhaled by the human body and causing harm. In addition, it can also avoid cross-contamination of dust and reagents, protecting the external environment and the safety of the personnel in the chamber. Negative pressure weighing room cleaning procedures mainly include the following steps: 1、Preparation of tools and supplies: including cleaning cotton, clean rags, tape, brushes, cleaners, weighing instruments, and so on. 2, close the weighing room door: before starting to clean, you need to close the weighing room door to prevent outside dust and debris into the weighing room. 3、Cleaning: Use clean rags to wipe the materials inside the weighing room, especially some easily overlooked corners and crevices. Use tape to seal the opening of the weighing chamber to prevent debris from entering. Use a brush to remove dust and debris from the weighing chamber. 4, clean the glass door and door handle: by the order from top to bottom, take another piece of clean cloth soaked with water and wrung out, wipe the weighing isolator wall and each differential pressure table, plexiglass door and door handle, the outside of the electronic control box. 5、Wipe the inside of the electric control box with a dry clean cloth in case of power failure. 6, in the external surface of the equipment cleaning: by the order from top to bottom, another piece of clean cloth with injected water soaked and wrung out, in turn, will be weighed to isolate the outer wall and the differential pressure table, plexiglass door, and door handle, the outside of the electronic control box. 7, the above clean parts of the repeated wipe 3-4 times, and then wring out a clean cloth to wipe again. After each wipe, the clean cloth for scrubbing and water, each time for a basin of water about 3-5 liters or so. 8, after the end of cleaning, the clean parts of the inner wall of the equipment after cleaning once, and then repeat the wipe, and finally wring out a clean cloth to wipe again. 9, after each wipe, the clean cloth for scrubbing and water, each time for a basin of water of about 3 liters or so. Then soaked with disinfectant and wrung out, the clean laminar flow car surface for comprehensive wipe disinfection. The above information is for reference only. Specific cleaning procedures may vary depending on the actual situation. |

German

German French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korrean

Korrean Russian

Russian