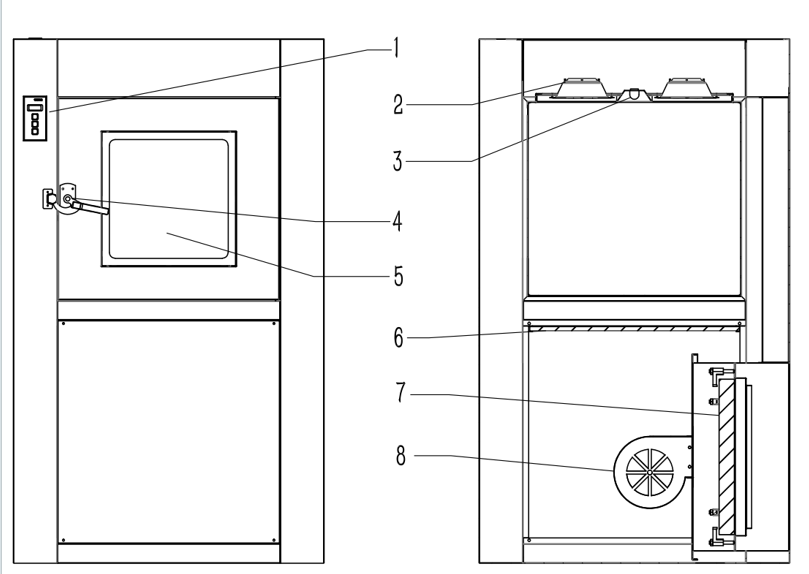

What are the structural characteristics of the air shower transfer window? What is the wind speed?The air shower transfer window is produced as a reference to the style of the air shower room. Compared with the ordinary transfer window, it adds high-efficiency filters, primary effect filters, stainless steel nozzles, and other equipment to efficiently blow out items. When transferring items, it can automatically purify the airflow in the work area through the fan and high-efficiency filter, and circulate the purified clean air flow to the work area, thus dynamically maintaining the cleanliness in the work area. Effectively prevents cross-contamination of rooms on both sides of the transfer window. It is equipped with an ultraviolet germicidal lamp inside, which can effectively kill microorganisms and bacteria growing in the work area, thereby more reliably ensuring the cleanliness of the work area.The fan quickly blows the air out through the high-efficiency filter and turns it into clean air. The clean air is sprayed out by the stainless steel spray with an airflow speed of up to 20M/S or more, which can effectively and quickly remove dust particles attached to the surface of the object. After the circulating air is passed through the primary filter, the double filtration and purification effect is remarkable and practical. The air shower transfer window is a device that provides a partially dust-free and sterile high-clean working environment. It can meet the special requirements for the working environment in the medical, biopharmaceutical, electronic optics, chemical, food, precision instrumentation, scientific research, and other industries. Generally speaking, many manufacturers produce air shower transfer windows with specific performance based on the requirements for clean rooms. Therefore, each manufacturer has a little difference in the function and process of air shower transfer windows. However, as a transfer window manufacturer, For environmental purification, the air shower transfer window production chain has the following characteristics and requirements, and the following product performance characteristics are adopted: 1. Modular design: more convenient transportation and more flexible assembly. 2. High reliability: The special high-efficiency filter used in the operating room has a good filtration and purification effect; the purified airflow passes through the double-layer flow equalizing membrane, and the air supply air flow is uniform. 3. Convenient maintenance: The installation frame of the flow equalizing film is fixed with a circlip, which is more convenient for maintenance. working principle: The air in the air shower transfer window is mainly internal circulation. The air passes through the primary effect filter. The fan quickly blows out the air that has passed through the primary effect filter, and then is absorbed by the high-efficiency filter to become clean air. The clean air is sprayed at high speed from the nozzle. The airflow speed is as high as 20m/s or more, which can effectively and quickly remove dust particles attached to the surface of objects. The air containing floating dust is then sucked into the primary filter, and the cycle repeats. The structure of the air shower transfer window is also very similar to that of the air shower room. Although there are differences in body size, many combinations are relatively consistent. You can refer to the following structural diagram:

1. Control panel; 2. Nozzle; 3. Germicidal lamp; 4. Rotary handle; 5. Double-layer glass window; 6. Primary filter; 7. Liquid tank high-efficiency filter; 8. Centrifugal fan Optional accessories: 1. Barometer 2.Intercom device 3.Ultraviolet germicidal lamp 4. Scope The above is an introduction to the structure of the air shower transfer window. Air shower transfer windows with non-standard sizes can be customized according to different usage scenarios. When installed and used, they can be connected to the production chain and directional use environment of the clean area, as well. Achievable. |

German

German French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korrean

Korrean Russian

Russian