H14 hepa filter HEPA has what needs to pay attention to the characteristics of the

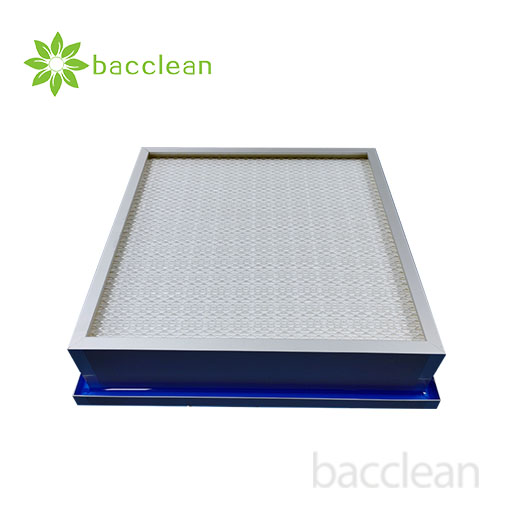

H14 hepa filter HEPA has what needs to pay attention to the characteristics of theHEPA as a clean room more ideal terminal filter supporting equipment, H14 high-efficiency filters are more widely used in many industrial clean rooms, cleanliness level greatly affects the cleanliness level of the clean area whether it meets the standard, and then affects the quality of the experiment or production. As high-efficiency filters are divided into various grades due to their effectiveness, according to the European EN779 standard classification, H14 high-efficiency filters belong to the higher grade filters with high filtration precision, which can filter different tiny particles in the air. As a high-efficiency filter manufacturer, Foshan Zhongjing has a larger quantity of H14 high-efficiency filters shipped and pays more attention to the production requirements of high-efficiency filters. Because these occasions have higher requirements for air cleanliness, the use of high-efficiency air filters can meet their requirements for air cleanliness.High-efficiency filter H14 is widely used in the end filtration of the purification system, odor small particles are likely to be intercepted by it outside, but also applies to laboratories, pharmaceutical factories, semiconductor manufacturing, microelectronics industry, and other areas.  According to the relevant international standards, high-efficiency air filters for 0.3μm (micron) of fine particles have a filtration efficiency of up to 99.99%, while the Foshan Zhongjing H14 high-efficiency filters produced by the requirements of at least 99.999% or more before being allowed to leave the factory. But for some manufacturers to produce depending on the situation, in order just to reduce production costs, often can not reach this indicator, and false high parameters lead to cleanliness far from reaching acceptance. Therefore, when we choose high-efficiency filters, we should choose the right reputation, stable production manufacturers, especially well-known manufacturers are more secure. As the H14 high-efficiency filter, more special attention is to the material, high-efficiency air filters generally use fine glass fibers for filtration materials, good filtration efficiency, offset paper, an aluminum film, and other materials for the splitter plate, glued with wooden frames, aluminum alloy, the use of silicone rubber for the odorless surface will not be hardened for a long time will not be cracked nature and stability, corrosion resistance, can absorb the stress generated by thermal expansion and contraction and will not crack, soft, moderate hardness, good elastic recovery. Moderate hardness, good elastic recovery. Some cleanroom special requirements are generally tested by the sodium flame method, with high filtration efficiency, low resistance, and large dust capacity. Among them, the liquid tank-type high-efficiency air filter produced by Bailun has special requirements for its products: 1, beautiful appearance, good sealing performance, easy installation, lightweight, thin thickness, high filtration efficiency; 2, high-efficiency filters in contact with the wind mouth using a special liquid tank sealant, permanent self-adhesive, elastic, in the aluminum tank can form a closed airtight sealing effect, and the knife mouth sealing use. 3, has a large filter area, long service life, low resistance, and other characteristics;  In addition, for the structure and operating conditions of H14 liquid tank-type high-efficiency air filters, the material is also quite concerned about the following characteristics of the material used in production: 1, filter media: ultra-fine glass fiber, imported materials; 2、Sealant: liquid tank special sealant (polyurethane); 3, separator: imported hot melt adhesive; 4、Frame: aluminium profile with anodized surface; 5、Others: double-sided spraying diamond mesh. |

German

German French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korrean

Korrean Russian

Russian